Our

Locations

We don’t just perform to your standards,

we set standards.

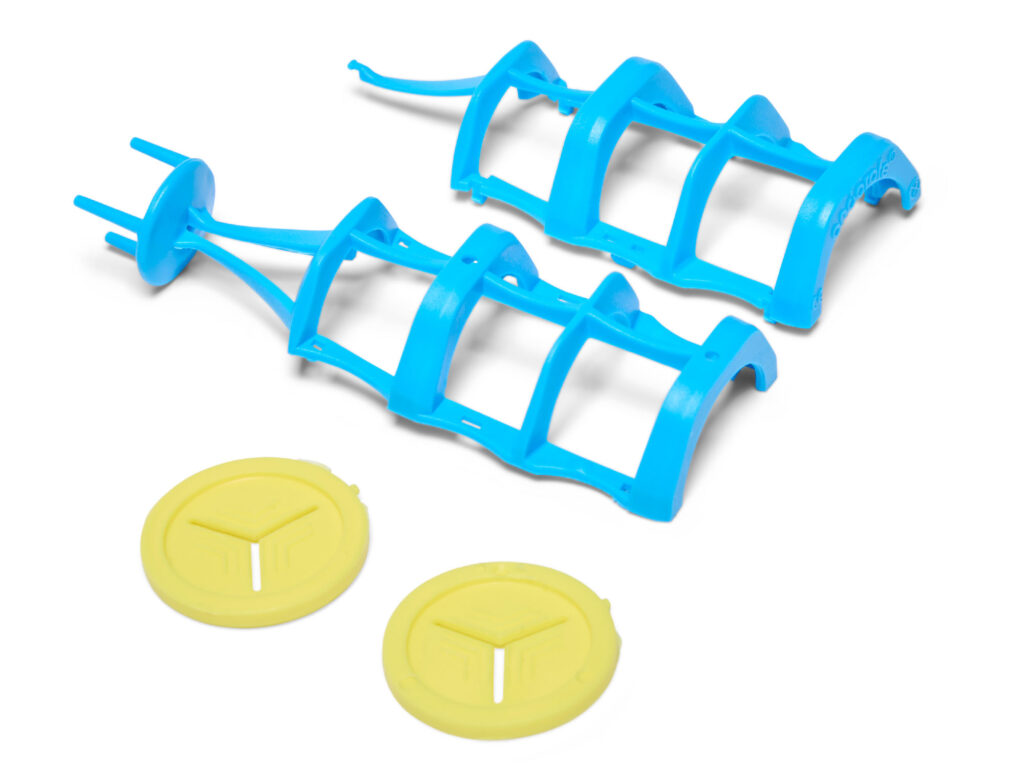

Built on decades of expertise in injection moulding & polymer development, we provide fully integrated manufacturing from NPI and tooling through to moulding, secondary operations, testing, and quality control. Our state-of-the-art Irish facility supports small to high-volume production for medical, life science, and semiconductor customers. As an ISO 9001 and ISO 13485 certified manufacturer, we continually invest in advanced equipment to ensure consistent, compliant, and highly reliable outcomes.

PEOPLE

-

7 Management & Support Staff

-

6 Manufacturing Specialists

FACILITIES

Head Office – Dublin

- 3,200 sq. ft. of modern office space

Manufacturing Campus

• 0.5-acre site featuring 10,600 sq. ft. of facilities

EQUIPMENT

- Machine Range: State-of-the-art presses covering 0.01 g to 2.5 kg shot weight

- Testing Labs: Incoming materials checked for rheological & mechanical properties and moisture (pre/post drying)

- Data Output: Real-time process monitoring & recording via a modern data acquisition platform, customer-viewable

- In-Mould Monitoring: Cavity pressure control for shot-to-shot consistency

- Traceability: Part-to-part traceability with full processing parameters per component

PEOPLE

-

7 Management & Support Staff

-

6 Manufacturing Specialists

FACILITIES

Head Office – Dublin

- 3,200 sq. ft. of modern office space

Manufacturing Campus

• 0.5-acre site featuring 10,600 sq. ft. of facilities

EQUIPMENT

- Machine Range: State-of-the-art presses covering 0.01 g to 2.5 kg shot weight

- Testing Labs: Incoming materials checked for rheological & mechanical properties and moisture (pre/post drying)

- Data Output: Real-time process monitoring & recording via a modern data acquisition platform, customer-viewable

- In-Mould Monitoring: Cavity pressure control for shot-to-shot consistency

- Traceability: Part-to-part traceability with full processing parameters per component

Complete end-to-end delivery, from NPI/DFM and tooling to horizontal and vertical moulding (up to 400T), including secondary operations, testing, and quality control for small to large production volumes.

Sectors

Medical Technology

Electronics & ICT

Food & Agri-Food

Biopharma

Projects

Testimonials

Our Clients