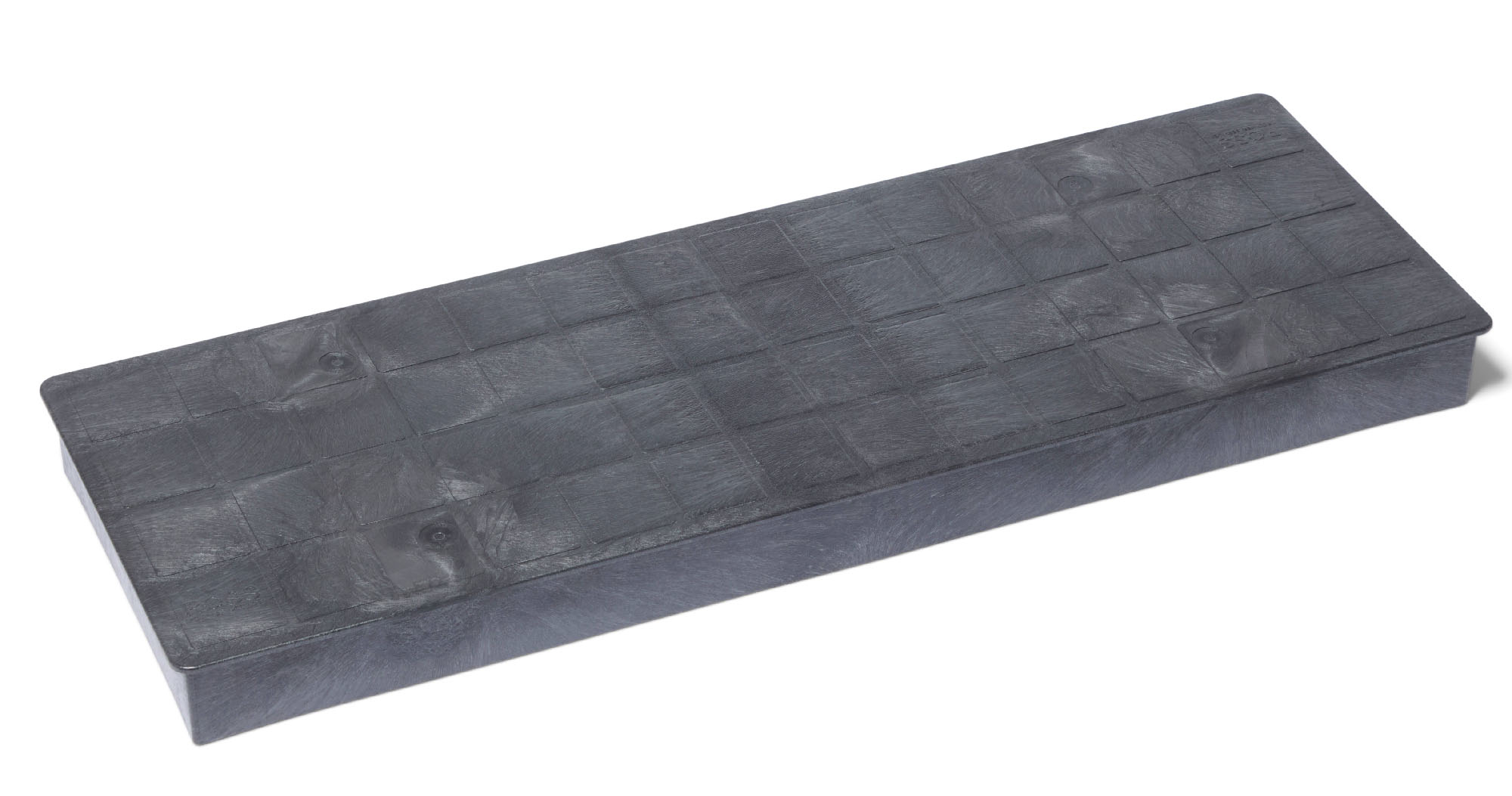

ROSS Polymer designed, patented, and manufactured an injection-moulded MEP penetration cover system for use in mission-critical environments. Originally developed for the semiconductor sector, where contamination control, precision, and reliability are paramount the patented system has since been successfully deployed across pharmaceutical, life sciences, and data centre facilities.

The product was engineered to achieve Class 10 cleanroom performance, providing a controlled, contamination-resistant solution for sealing service penetrations through floors, walls, and ceilings. UV-resistant and fire-retardant polymer materials were carefully specified to meet applicable European and North American fire performance standards, ensuring regulatory compliance, life-safety performance, and long-term durability in demanding operational environments.

Manufactured using precision injection moulding, the patented system delivers consistent quality, tight dimensional tolerances, and rapid, repeatable installation. The design supports both new-build and retrofit applications while maintaining cleanroom integrity and minimising installation risk on site.

Scope of Design & Delivery

- In-house product design and development

- Cleanroom-compliant structural and material engineering

- Specification of UV-resistant and fire-retardant polymers

- Injection moulded manufacture with tight tolerances

- Deployment across mission-critical facilities